PRODUCTS

PRODUCTS

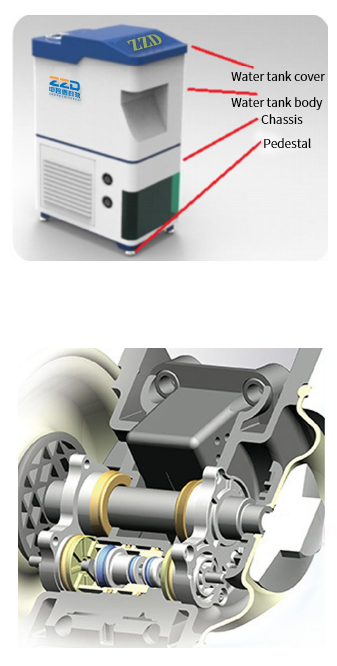

Cutting fluid oil and water regeneration device

subcategory:

Machine tool peripheral products

keyword:

Cutting fluid oil and water regeneration device

Detailed introduction

Status statement

In order to improve the processing of CNC machine tools, after the spindle slide oil and cutting oil flow into the centralized tank, the processing will emulsify and deteriorate the oil, and then the oil emulsification will form a layer of oil film, isolating the air and water. In this case, when the machine stops running, the mold in the water begins to multiply, and then produce odor, more attached to the oil layer, when running through the suction tank, the water is sucked into the processing tank by the beating of the tool to form fog to achieve the efficiency of heat loss, but because of this, so the operator also follows the inhalation of the same with mold, oil smoke, odor fog. The dirt also sticks to the inside of the machine, in the long run will make the accuracy of the machine greatly affected, the health of the operator is also lost, in addition, according to the normal replacement time of the cutting fluid is once every three months, if the machine is not regularly replaced, the cutting fluid will be too acidic and then corrode the machine so that it has a failure event, or the operator often comes into contact with the cutting fluid and when the cutting fluid mold is too much, Skin contact after a period of time will make the operator's skin rash, even severe skin ulceration.

Product highlights

◆ Greatly improve the service life of cutting fluid, reduce costs, improve product finish

◆ Eliminate cutting fluid replacement frequency, waste oil recovery, safety and environmental protection

◆ High strength constant temperature cooling to improve tool life

◆ Safe independent complete system, low cost, no consumables, maintenance-free, small footprint

◆ The core parts of the imported diaphragm pump make the cutting fluid quickly and completely separate oil and water

◆ Ultra-precision special filter device separation more complete purification

◆ Standard, environmental protection, energy saving and high efficiency

Water isolation purification oil water separation removal cutting constant temperature cooling enhance cutting life reduce tool cost Environmental protection improve quality

Improve results

After the actual use, the average three days can make the cutting fluid of one of our machines achieve the effect of oil removal, sterilization, deodorization, such results really meet the needs of our company, but also improve the oil emulsion deterioration mold growth, the machine is easy to dirty and difficult to clean, the discomfort caused by long-term contact, and the cutting fluid does not need to be replaced (save replacement costs) and so on. In the consumable part, the built-in structure of the machine adopts no consumable design, and the filter core only needs to be cleaned regularly. This design also saves a sum of consumable costs for our company.

Higher stability

◆ Compressed air drive, no motor, reducer and other additional electric configuration, no mechanical seal, maximize the reduction of leakage and unexplained shutdown, to ensure the stability and continuity of production.

◆ Air valve design with patented technology, no lubrication, zero dead point. High adaptability to all types of compressed air, providing reliable and worry-free operation.

◆ Self-priming, maximum suction range (wet) up to 9.2 meters, suitable for a variety of installation conditions, can replace some submersible pump.

◆ Can run dry for a long time, and there will be no temperature rise and damage to the components. Avoid safety hazards and production risks.

Greater versatility

◆ Each wet part of the fluid section has a variety of materials to choose from, which is suitable for different industries and different materials. Whether it is wear type media, corrosive media, or high/low temperature media, there are special pumps to match it.

◆ Multi-interface customized design, convenient for OEM customers to use in different installation Spaces and piping systems.

◆ Wide flow range, can provide 1/4 inch to 3 inch different size pump, fluid coverage of 1lpm~800Ipm.

Easier maintenance

◆ Modular structure design, reduce the number of parts, reduce maintenance time and cost, maximize the life cycle cost of equipment.

◆ Fewer wearing parts, no rotating parts in the equipment, reduce the wear rate and the number of worn parts.

◆ Small size, light weight, no additional maintenance space and maintenance personnel.

◆ Humanized design, maintenance without special tools or lifting tools.

Machine tool peripheral products

Application

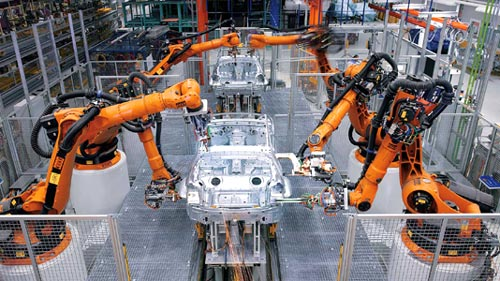

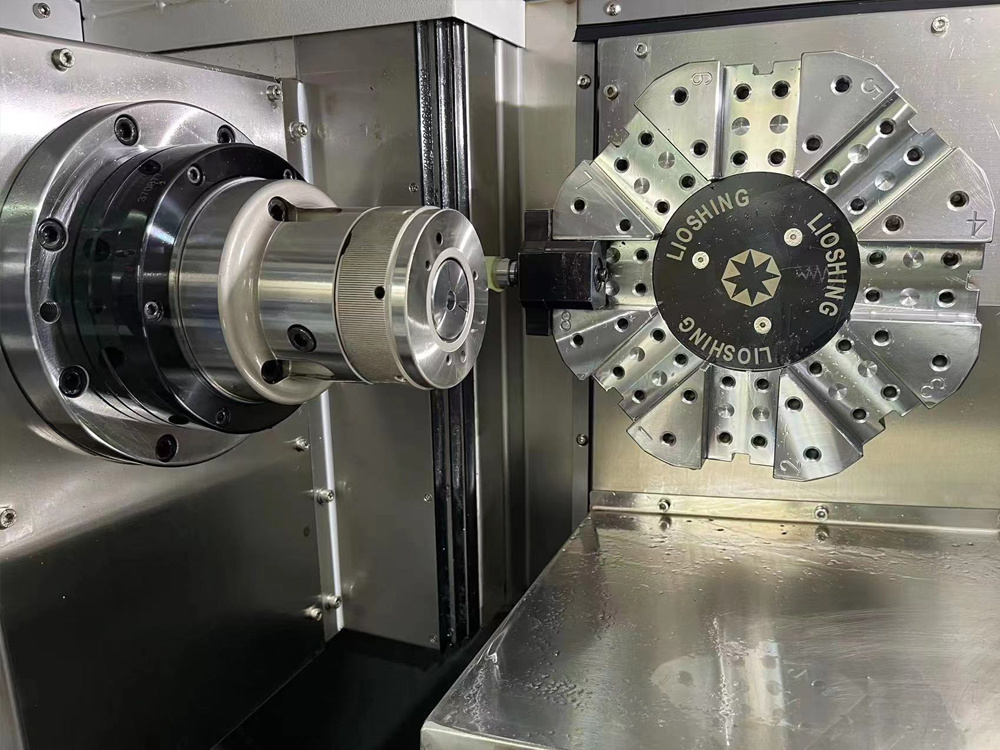

Its products are CNC precision lathes, machining centers, multi-axis compound turning and milling machine series, widely used in pneumatic hydraulic, auto parts, home appliances and sanitary ware, medical equipment and military aviation and other industries.

Packing and transportation

In order to serve new and old users in a full range, reduce costs for users, improve efficiency, and enable users to obtain a return on investment, the company's business involves from machine tool manufacturing, equipment maintenance and technology development, precision manufacturing, machine tool accessories and automated manufacturing services, to solve users in product research and development, manufacturing, precision environmental protection, high precision and high efficiency and other related technical problems;

|

|

|

|

|

|

|

|

Customer service

In order to serve new and old users in a full range, reduce costs for users, improve efficiency, and maximize the return on investment, the company's business involves machine tool research and development and manufacturing and machine tool application services, to solve users in product research and development, manufacturing, precision environmental protection, high precision and efficient and other related technical problems, diversified, deep and efficient customer management mechanism.

Cooperative enterprise

Automobile industry

Military industry

Other industries

Certification

Over the years, DeHaotong company has been deeply engaged in research, taking the road of independent research and development and close cooperation with foreign technology, successfully applied for a number of patent technology certification, and won the high-tech enterprise qualification certificate, the company focuses on the development and manufacturing of high precision CNC machine tools, and has passed the ISO9000 international quality system certification;

Leave us a message and consult the products you need

Please fill in your phone number, which will help us get in touch with you in time and solve your problems as soon as possible