PRODUCTS

PRODUCTS

Automatic CNC lathe

subcategory:

Zorui series

keyword:

Automatic CNC lathe

Detailed introduction

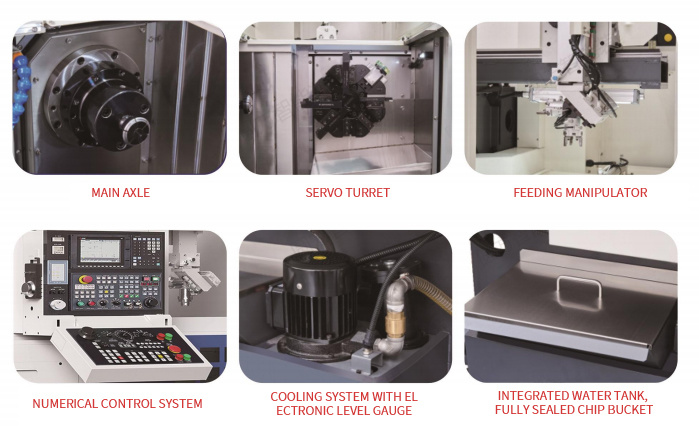

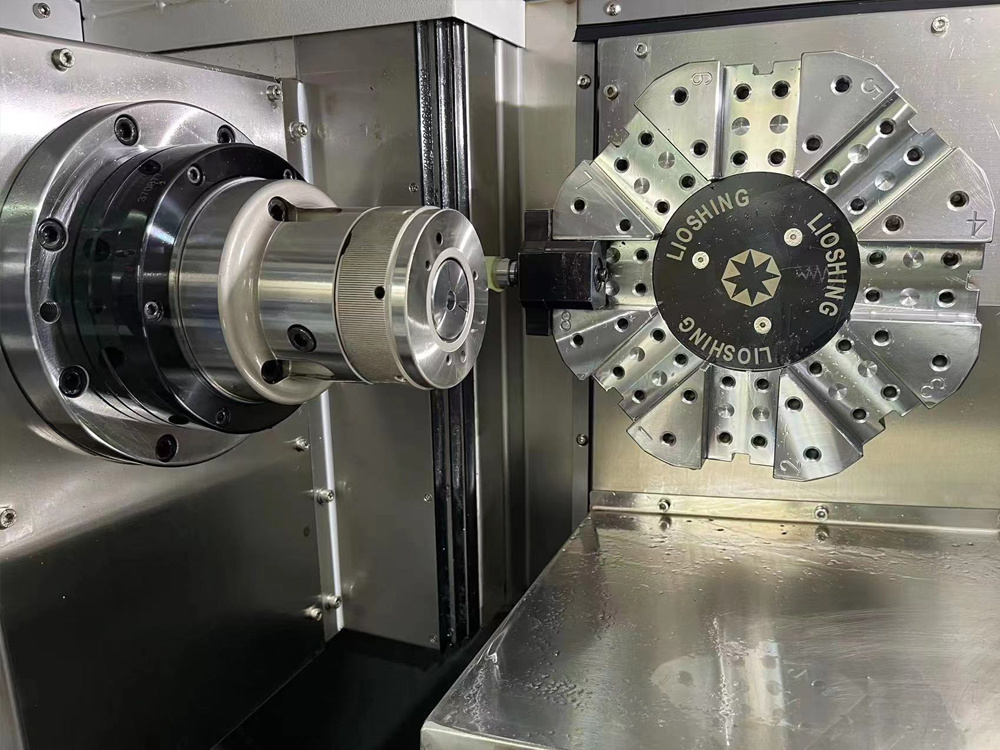

High precision

High-rigidity, integrally cast low-center of gravity bed ensures stable processing.

Precision machined and assembled motion mechanism. The unique structure and control method ensure the smallest thermal deflection and the repeatable positioning accuracy is 0.002mm.

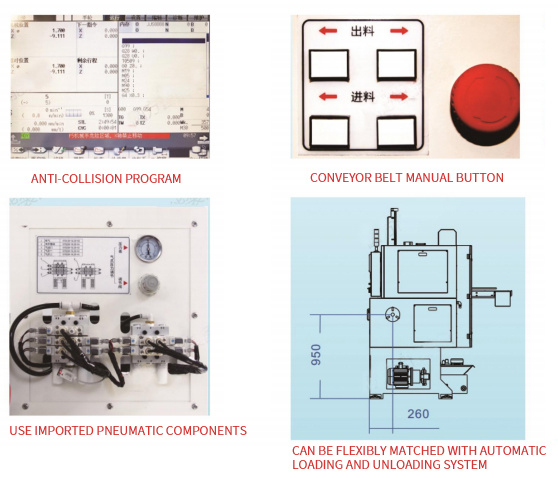

Automate

The machine integrates feeding and handling manipulators for large-batch or small-batch multi-variety processing. Automatic production line can be selected to support up to 10 machine groups. Optional automatic chip removal machine, can be customized bin.

High configuration

The standard online detection device can realize the constant detection of processed products and avoid the occurrence of bad product batch. At the same time, the standard manipulator can automatically turn over function, which can realize the automatic completion of two processes of one machine.

| Model | ZD-C36 | |

| Processing capacity | Maximum processing diameter of bar | 34mm |

| Maximum machining diameter | 200mm/85 (automatic loading and unloading) | |

| Maximum machining length | 120mm/70 (automatic loading and unloading) | |

| controller | Mitsubishi E80/M80 (optional) | |

| CNC system | interface | A2-4 |

| Spindle motor | 3.7/5.5KW | |

| Spindle speed | 60-6000 rpm | |

| spindle | Shank height | 20mm |

| Station | 8 | |

| Dotret | X-axis | 145mm |

| Z轴 | 145mm | |

| itinerary | X-axis ball screw | 3210 |

| Z-axis ball screw | 3210 | |

| Feed | Bed | The turret is arranged vertically with the spindle and the bed is cast as a whole |

| Protection | High-quality fully protected inner anti-horse sheet metal cover | |

| Machine size | Machine tool area | 1600*1700mm |

| Machine height | 2300mm | |

| Machine weight | 2400kg | |

| Standard attachments | ||

| 1. Standard hydraulic chuck; 2. Hydraulic rotary cylinder; 3. 8 stations with the same turret; 4. 2 tool holders; 5. 8 knife pressing blocks; 6. Cooling pump and cooling water tank; 7. Fully protected rice gold; 8. Automatic lubrication system; 9. Feeding manipulator and conveyor belt. | ||

| Matching | ||

| 1. Automatic bar feeder; 2. Automatic chip conveyor; 3. Online detection; 4. Automatic flipping. | ||

Machine tool peripheral products

Application

Its products are CNC precision lathes, machining centers, multi-axis compound turning and milling machine series, widely used in pneumatic hydraulic, auto parts, home appliances and sanitary ware, medical equipment and military aviation and other industries.

Packing and transportation

In order to serve new and old users in a full range, reduce costs for users, improve efficiency, and enable users to obtain a return on investment, the company's business involves from machine tool manufacturing, equipment maintenance and technology development, precision manufacturing, machine tool accessories and automated manufacturing services, to solve users in product research and development, manufacturing, precision environmental protection, high precision and high efficiency and other related technical problems;

|

|

|

|

|

|

|

|

Customer service

In order to serve new and old users in a full range, reduce costs for users, improve efficiency, and maximize the return on investment, the company's business involves machine tool research and development and manufacturing and machine tool application services, to solve users in product research and development, manufacturing, precision environmental protection, high precision and efficient and other related technical problems, diversified, deep and efficient customer management mechanism.

Cooperative enterprise

Automobile industry

Military industry

Other industries

Certification

Over the years, DeHaotong company has been deeply engaged in research, taking the road of independent research and development and close cooperation with foreign technology, successfully applied for a number of patent technology certification, and won the high-tech enterprise qualification certificate, the company focuses on the development and manufacturing of high precision CNC machine tools, and has passed the ISO9000 international quality system certification;

Leave us a message and consult the products you need

Please fill in your phone number, which will help us get in touch with you in time and solve your problems as soon as possible