PRODUCTS

PRODUCTS

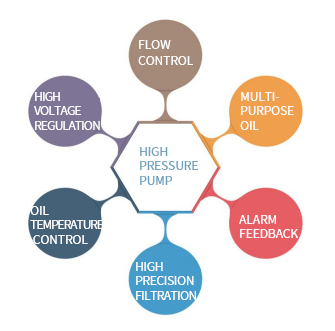

Innovative high pressure pump

subcategory:

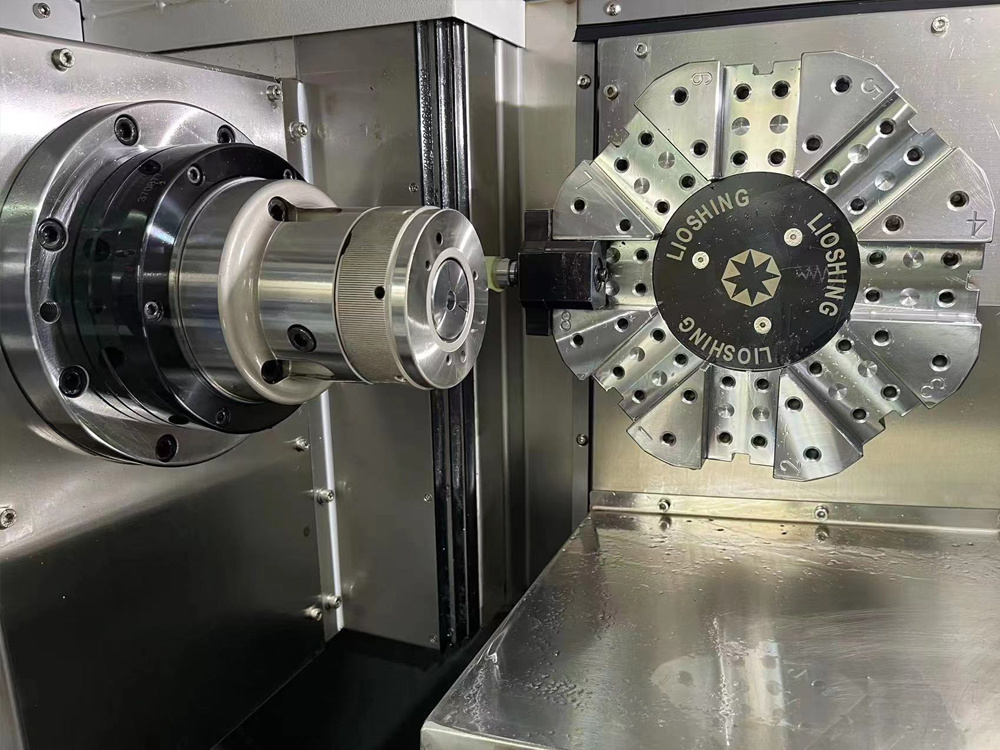

Machine tool peripheral products

keyword:

Innovative high pressure pump

Detailed introduction

◆ Our economical high-pressure pump, pressure 100-200BAR. Four-way M code module components.

◆ PLC multi-point logic function control, strong anti-interference ability, low failure rate.

◆ With pressure monitoring and alarm prompt function, humanized visual monitoring.

◆ The oil tank comes with oil temperature and liquid level detection function.

◆ It has an oil filtration system failure alarm device to improve the service life of the pump.

◆ Customized imported pump head.

◆ Ultra-precision multiple filtration system, filtration accuracy of 3 microns, with oil supply pump to supply oil to the oil tank turnover area.

◆ Energy-saving oil temperature constant control system.

◆ Unique oil circuit design reduces the system oil temperature.

◆ Humanized design, perfect combination of beauty and safety protection, with its own tool drawer.

Technical parameters

| description | unit | GY70 | GY100 | GY200 | |

| Motor | power | KW | 3.75 | 4 | 5.5 |

| voltage | In | 220/380 | 220/380 | 380 | |

| Gear pumps | Displacement range | L/min | 23 | 30 | 40 |

| Filtration accuracy | micron | 30 | 20 | 3 | |

| Solenoid valve | voltage | In | 24/220 | 24/220 | 24/220 |

| Thermostatic device | Input power | KW | — | 0.24 | 0.35 |

| pressure | Maximum pressure | bar | 70 | 100 | 150 |

| Control the oil circuit | Oil outlet | L | 4 | Extensible5 | Extensible5 |

| Fuel storage tank | Oil storage | L | 50m | 120m | 200 L |

| Floor space | Length/width/height | mm | 500x500x1100 | 540x600x1000 | 840x690x1100 |

| weight | Medical history | 280 | 300 | 380 | |

Optional configuration

1. Touch screen display

1. Touch screen display

2, flow monitoring feedback

3, oil temperature cooling device

4, oil mist collection function

5, oil smoke exceeding standard alarm

6, filter system self-cleaning function

7, equipment maintenance alarm prompt

8, multi-return oil circuit M code control (more than 4)

| High-pressure mode | Cycle time (S/PCS) | Day shift (20 H) | Annual production (30 days) | Actual benefits (1.5 RMB/PCS) |

| Innovative high pressure | 60S | 1200 | 360,000 | ¥ 540,000 |

| Traditional high pressure | 90S | 800 | 240,000 | ¥ 360,000 |

| Machine cooling | 110S | 654 | 196 , 000 | ¥ 294,000 |

Time is cost, efficiency is profit.

Time is cost, efficiency is profit.

The working time is 60 seconds, and the annual output of the order is 100,000, which takes 83 days

The working time is 90 seconds, and the annual output of the order is 100,000, which takes 125 days

The working time is 110 seconds, the annual output of the order is 100,000, and it takes 153 days

Total savings of 70 days

Total savings of 70 days

①(utilities + workers' wages + overtime pay + cutting tool fee + equipment wear cost) Estimated cost 300 yuan/day x70 days =21,000(RMB)

② The turnover generated by each equipment is 1000 yuan/day X70 days =70,000(RMB)

Increase production capacity, reduce investment, increase profits, reduce costs, and optimize quality.

Machine tool peripheral products

Application

Its products are CNC precision lathes, machining centers, multi-axis compound turning and milling machine series, widely used in pneumatic hydraulic, auto parts, home appliances and sanitary ware, medical equipment and military aviation and other industries.

Packing and transportation

In order to serve new and old users in a full range, reduce costs for users, improve efficiency, and enable users to obtain a return on investment, the company's business involves from machine tool manufacturing, equipment maintenance and technology development, precision manufacturing, machine tool accessories and automated manufacturing services, to solve users in product research and development, manufacturing, precision environmental protection, high precision and high efficiency and other related technical problems;

|

|

|

|

|

|

|

|

Customer service

In order to serve new and old users in a full range, reduce costs for users, improve efficiency, and maximize the return on investment, the company's business involves machine tool research and development and manufacturing and machine tool application services, to solve users in product research and development, manufacturing, precision environmental protection, high precision and efficient and other related technical problems, diversified, deep and efficient customer management mechanism.

Cooperative enterprise

Automobile industry

Military industry

Other industries

Certification

Over the years, DeHaotong company has been deeply engaged in research, taking the road of independent research and development and close cooperation with foreign technology, successfully applied for a number of patent technology certification, and won the high-tech enterprise qualification certificate, the company focuses on the development and manufacturing of high precision CNC machine tools, and has passed the ISO9000 international quality system certification;

Leave us a message and consult the products you need

Please fill in your phone number, which will help us get in touch with you in time and solve your problems as soon as possible