PRODUCTS

PRODUCTS

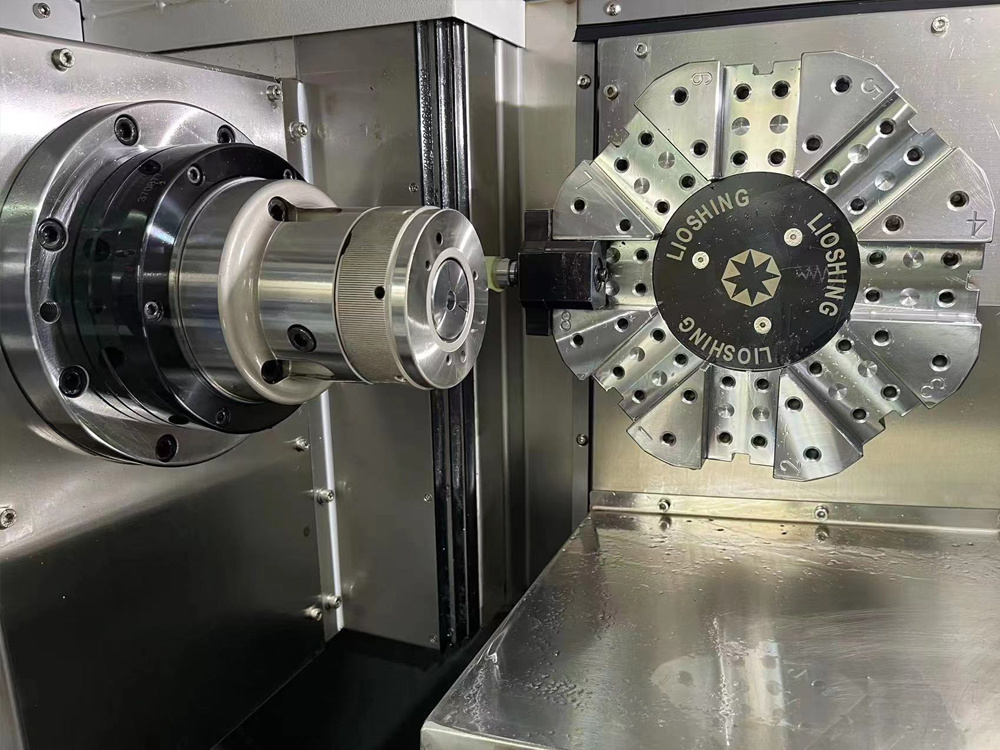

Double spindle drilling and milling center

subcategory:

Jierui series

keyword:

Double spindle drilling and milling center

Detailed introduction

Mechanical characteristics

The machine tool is equipped with double high-speed spindle, which can process two identical parts at one time, improve the double machining efficiency, the machine tool is equipped with a double tool magazine, the servo tool change efficiency is high, and the tool length is automatically corrected, which is conducive to batch processing. The high-speed processor system independently develops software design. The tool magazine can change tools asynchronously at phase frequency, and has a dual-spindle high-speed co-frequency tapping, the first in the industry.

| Model | unit | ZD-G400 | ZD-G600 | ZD-G680 | |

| workbench | Working size | mm | 1000*420 | 1300*600 | 1300*600 |

| T-slot (number of slots wide spacing) | / | 3*18*134 | 5*18*125 | 5*18*125 | |

| Maximum load-bearing | Medical history | 400 | 800 | 800 | |

| itinerary | X/Y/Z1/Z2 axis travel | mm | 450/400/300/300 | 700/700/300/300 | 700/700/300/300 |

| The distance from the center of the spindle to the column | mm | 440 | 740 | 820 | |

| Spindle end face to table | mm | 175-475 | 170-475 | 170-475 | |

| Dual spindle distance | Relative distance of the two spindles | mm | 400 | 740 | 820 |

| Maximum part size (length * width) | mm | 400*400 | 600*700 | 680*800 | |

| Spindle 1 | Spindle speed | rpm | 20000 | 20000 | 20000 |

| Spindle dimensions | / | BT30 | BT30 | BT30 | |

| Spindle 2 | Spindle speed | rpm | 20000 | 20000 | 20000 |

| Spindle dimensions | / | BT30 | BT30 | BT30 | |

| velocity | The X/Y/Z1/Z2 axes move quickly | m/min | 60/60/48 | 48/48/48 | 48/48/48 |

| precision | Positioning accuracy | mm | 0.005 | 0.005 | 0.005 |

| Repeatable positioning accuracy | mm | 0.003 | 0.003 | 0.003 | |

| Feed | Cutting feed | mm/min | 0-10000 | 0-10000 | 0-10000 |

| Guide rail formation | / | Linear guides | Linear guides | Linear guides | |

| Automatic tool changer/ATC | Knife array capacity | T | 21+21 (Dual Tool Magazine) | 21+21 (Dual Tool Magazine) | 21+21 (Dual Tool Magazine) |

| Maximum knife diameter (full knife) | mm | φ80 | φ80 | φ80 | |

| Maximum tool diameter (adjacent tool) | mm | φ140 | φ140 | φ140 | |

| Maximum tool weight | Medical history | 3 | 3 | 3 | |

| Tool change time | S | 1.3 | 1.3 | 1.3 | |

| system | System configuration | / | Mitsubishi | Mitsubishi | Mitsubishi |

| other | Spindle motor power | Kw | 55175*2 | 55/7.5*2 | 55/7.5*2 |

| X/Y/Z three-axis motor power | Kw | 1.5/1.5/3.0 | 1.5/1.5/3.0 | 1.5/1.5/3.0 | |

| Machine weight | Medical history | 3900 | 5800 | 6200 | |

| Machine size | mm | 1820*2205*2480 | 2900*2950*2650 | 3000*2950*2650 | |

Machine tool peripheral products

Application

Its products are CNC precision lathes, machining centers, multi-axis compound turning and milling machine series, widely used in pneumatic hydraulic, auto parts, home appliances and sanitary ware, medical equipment and military aviation and other industries.

Packing and transportation

In order to serve new and old users in a full range, reduce costs for users, improve efficiency, and enable users to obtain a return on investment, the company's business involves from machine tool manufacturing, equipment maintenance and technology development, precision manufacturing, machine tool accessories and automated manufacturing services, to solve users in product research and development, manufacturing, precision environmental protection, high precision and high efficiency and other related technical problems;

|

|

|

|

|

|

|

|

Customer service

In order to serve new and old users in a full range, reduce costs for users, improve efficiency, and maximize the return on investment, the company's business involves machine tool research and development and manufacturing and machine tool application services, to solve users in product research and development, manufacturing, precision environmental protection, high precision and efficient and other related technical problems, diversified, deep and efficient customer management mechanism.

Cooperative enterprise

Automobile industry

Military industry

Other industries

Certification

Over the years, DeHaotong company has been deeply engaged in research, taking the road of independent research and development and close cooperation with foreign technology, successfully applied for a number of patent technology certification, and won the high-tech enterprise qualification certificate, the company focuses on the development and manufacturing of high precision CNC machine tools, and has passed the ISO9000 international quality system certification;

Leave us a message and consult the products you need

Please fill in your phone number, which will help us get in touch with you in time and solve your problems as soon as possible