PRODUCTS

PRODUCTS

Intelligent crushing press

subcategory:

Machine tool peripheral products

keyword:

Intelligent crushing press

Detailed introduction

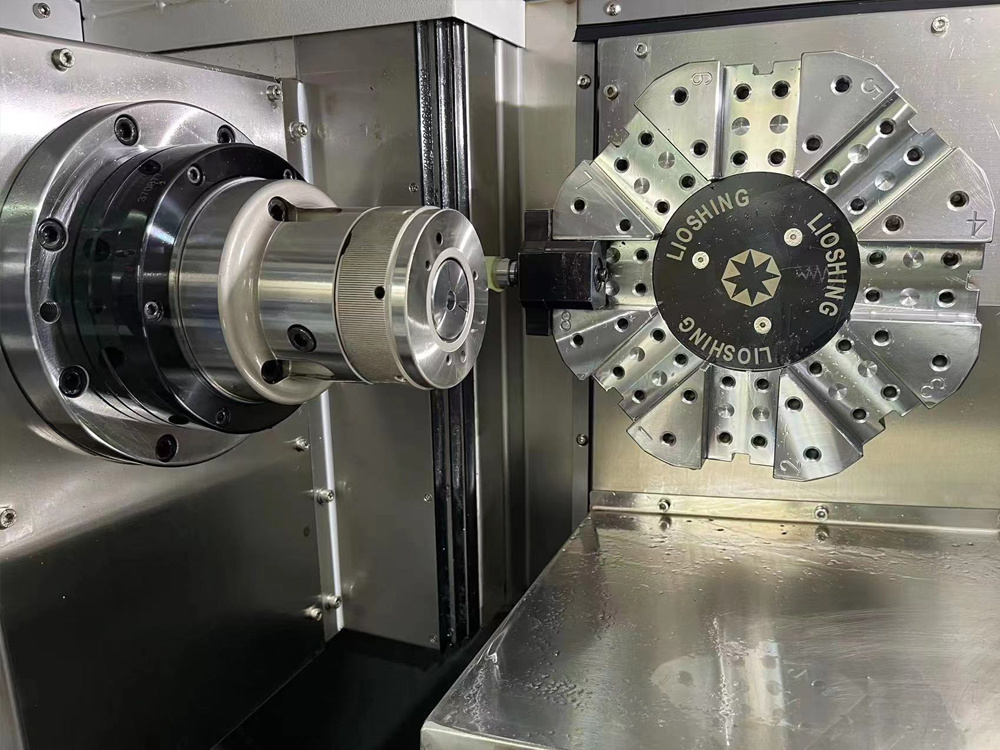

Intelligent iron cutting crushing briquetting machine for our original technology, design small and powerful, is an indispensable processing system in mechanical processing, the model needs to be in the automatic cutting machine under the transmission of iron cutting into the processing crushing and pressing, crushing system through the sensing signal of iron cutting crushing treatment, and quickly carry out briquette processing action, the iron cutting produced by the machine tool after the comprehensive pressing of our processing system into round cake iron block.

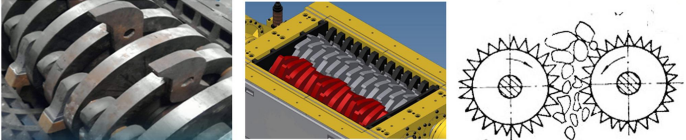

The equipment is compact and has a reasonable layout, high crushing efficiency, and the knives are cast with alloy steel, which is strong and has a long service life. Iron frame plate stiffeners are very strong against high torques. Easy to adjust, low maintenance, economical and durable. The equipment has low speed, low noise, high torque, and is equipped with mechanical and hydraulic electrical overload protection to extend the service life of the equipment and reduce the use and maintenance cost of the equipment.

The tooth knife has a unique design in terms of thickness, shape, arrangement order, etc., and has strong shear force, which can improve the shredding efficiency; The drive part adopts heavy-duty planetary gear reducer transmission; The bearing seat adopts split type, easy and convenient to disassemble and assemble the tooth changing cutter, good interchangeability of parts, outer frame structure of extra thick plate welding processing, strong rotating shaft of large angle hexagonal column, large-diameter solid feeding hopper suitable for shredding fine, difficult to crush iron cutting, with uniform discharge, controllable size, high crushing efficiency and other advantages, can be widely used in the machining industry in shredding operations.

The working principle is mainly by impact to crush the material into the crusher, suffered from the impact of the hammer head of high-speed rotation and broken, crushed materials, from the hammer head to obtain kinetic energy, high-speed rush to the frame body of the baffle, screen, at the same time the materials collide with each other, broken many times, less than the gap of the screen strip material discharged from the gap, individual larger materials, on the screen again by the impact of the hammer head, grinding and extrusion and broken, the material is extruded by the hammer head from the gap, so as to obtain the required particle size of the product.

Product Highlights

◆ The equipment adopts PLC automatic control, with semi-automatic and automatic operation functions.

◆ Our original rapid technology reduces the motor power by nearly doubling and achieves power saving and efficiency.

◆ With motor overload protection function, large material box design greatly improves work efficiency.

◆ Each hydraulic cylinder adopts fast technology to reduce energy consumption.

◆ The system is designed with pre-release device, which completely eliminates the hydraulic impact.

◆ This machine adopts hydraulic transmission, highly professional integral valve block, super large flow diameter, so that the system pressure loss is less, and the drawbacks of leakage are eliminated.

◆ The use of cartridge valve, electro-hydraulic proportional valve and unique oil circuit design make the hydraulic system perfect, even if it works under long-term heavy load, the system will not be powerless.

◆ According to the user's working conditions, screw automatic feeder, chain automatic discharger, etc. can be added to reduce the labor intensity of workers.

◆ Without adding any additives, all kinds of granular, powdered cast iron, aluminum, copper, magnesium, and silver can be pressed into high-density briquettes.

| Model | YK100 |

| Briquette size mm | φ60x8 |

| Motor power | 7kw |

| rotate speed | 1440 |

| Degree of crushing | 20mm wide |

| Suitable for the material | Continuous chips with a hardness of less than 1HRC such as aluminum, copper, iron and other hardness under 35mm thickness |

| Productivity t/h | Scrap iron:87-130Kg/h Aluminium scrap:30-45Kg/h |

| Hydraulic working pressure MPA | 7 |

| Briquette pressure T | 13 |

| The total weight of the machine tool is T | 1.2 |

Machine tool peripheral products

Application

Its products are CNC precision lathes, machining centers, multi-axis compound turning and milling machine series, widely used in pneumatic hydraulic, auto parts, home appliances and sanitary ware, medical equipment and military aviation and other industries.

Packing and transportation

In order to serve new and old users in a full range, reduce costs for users, improve efficiency, and enable users to obtain a return on investment, the company's business involves from machine tool manufacturing, equipment maintenance and technology development, precision manufacturing, machine tool accessories and automated manufacturing services, to solve users in product research and development, manufacturing, precision environmental protection, high precision and high efficiency and other related technical problems;

|

|

|

|

|

|

|

|

Customer service

In order to serve new and old users in a full range, reduce costs for users, improve efficiency, and maximize the return on investment, the company's business involves machine tool research and development and manufacturing and machine tool application services, to solve users in product research and development, manufacturing, precision environmental protection, high precision and efficient and other related technical problems, diversified, deep and efficient customer management mechanism.

Cooperative enterprise

Automobile industry

Military industry

Other industries

Certification

Over the years, DeHaotong company has been deeply engaged in research, taking the road of independent research and development and close cooperation with foreign technology, successfully applied for a number of patent technology certification, and won the high-tech enterprise qualification certificate, the company focuses on the development and manufacturing of high precision CNC machine tools, and has passed the ISO9000 international quality system certification;

Leave us a message and consult the products you need

Please fill in your phone number, which will help us get in touch with you in time and solve your problems as soon as possible